Özel Betonlar

Batıbeton, müşteri ihtiyaç ve beklentilerine uygun ürünleri, enerji verimli ve çevreye duyarlı teknolojiler kullanarak yüksek standartlarla üretmeyi hedefler.

Batıbeton DOĞA (Renkli)

Dekoratif ve estetik görünüm amacıyla değişik renklerdeki özel pigmentler ilave edilerek üretilen renkli betonlardır. Genellikle park, bahçe, spor tesisleri, otopark, yürüme yolları vb. sosyal amaçlı yapılan imalatlarda kullanılabilir.

Batıbeton İNCİ (Beyaz)

Dekoratif ve estetik görünüm amacıyla beyaz çimento kullanılarak üretilen beyaz renkli betonlardır. Özel mimari tasarım yapılan projelerde tercih edilmekte olup, boya veya sıva uygulanmayarak genellikle yapılan iç kısımlarında kullanılmaktadır

Batıbeton LİFLİ (Polipropilen)

Standart betonların içerisine polipropilen lif ilave edilerek üretilen betonlardır. İçeriğinde bulunan lifler sayesinde, betonun çekme dayanımına yaptığı olumlu etkiler plastik ve termal büzülme çatlaklarının oluşmasını ve oluşan çatlakların büyümesini engellemeye faydası bulunmaktadır. Genellikle yatay yapı elemanlarında (döşeme,zemin vb.) betonlarında kullanılmaktadır. Ayrıca yüksek sıcaklığa maruz kalan betonlarda da kullanılmaktadır.

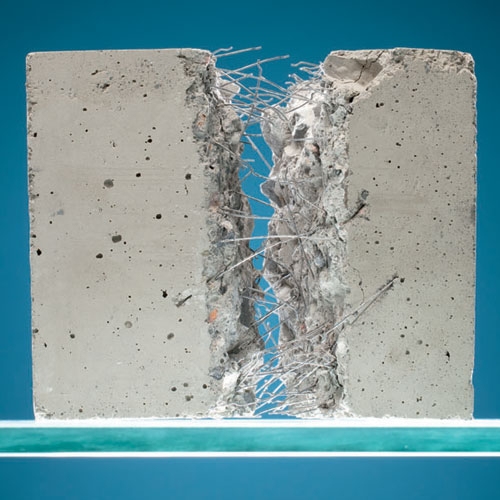

Batıbeton ÇELİK (Çelik Lifli)

Standart betonların içerisine çeşitli boyut ve miktarlarda çelik lif ilave edilerek elde edilen betonlardır. Batıbeton ÇELİK, daha esnek ve enerji yutma kapasitesi (tokluk) yüksek beton ihtiyacını karşılamak için üretilmekte olup, fabrikaların zemin betonlarında, beton yollarda, benzin istasyonu, otopark, araç parkı gibi dinamik yükler altında kalan zemin betonlarında kullanılabilir.

Batıbeton BULUT (Hafif)

Yapılarda hafif beton uygulamaları ihtiyacını karşılamak amacıyla üretilen, yoğunluğu 800 – 2000 kg/m3 olan betonlardır. Batıbeton BULUT, yapı yüklerinin azaltılması gereken durumlarda, ısı ve ses yalıtımı maksadıyla dökülecek betonlarda kullanılabilir.

Batıbeton GÜLLE (Ağır)

Literatürde ağır beton olarak adlandırılan ve yoğunluğu 2600 kg/m3’den büyük olan betonlardır. Batıbeton GÜLLE, özellikle zararlı ışınlara karşı bir perde oluşturmak amacıyla kullanılan betonlardır. Kullanım yerleri arasında nükleer santraller, hastanelerin röntgen film odalarının duvar kısımları gibi yapılar gösterilebilir.

Batıbeton GEÇİT (Poroz)

Yüksek su geçirgenliğine sahip, filtre özelliğine sahip, yalnızca iri agrega kullanılarak üretilen boşluklu ve geçirimli betondur. Halı saha tabanı, yol kenarları gibi drenaj gerektiren imalatlarda kullanılmaktadır.

Batıbeton ÖZGÜR (KYB)

“Kendiliğinden Yerleşen ve Sıkışan Beton” Vibrasyon ihtiyacı olmaksızın kendiliğinden yerleşme, sıkışma ve donatıları tamamen sarma yeteneğine sahiptir. Kendi ağırlığı ile istenilen kesite homojen bir şekilde yayılabilen, kesitte tam doluluğun sağlanabildiği, yüksek dayanım ve dayanıklılık gibi özellikleriyle yüksek performanslı betondur. Ayrıca yüksek bağlayıcı miktarı nedeni ile geçirimsizliği en başarılı olan betonlardandır.